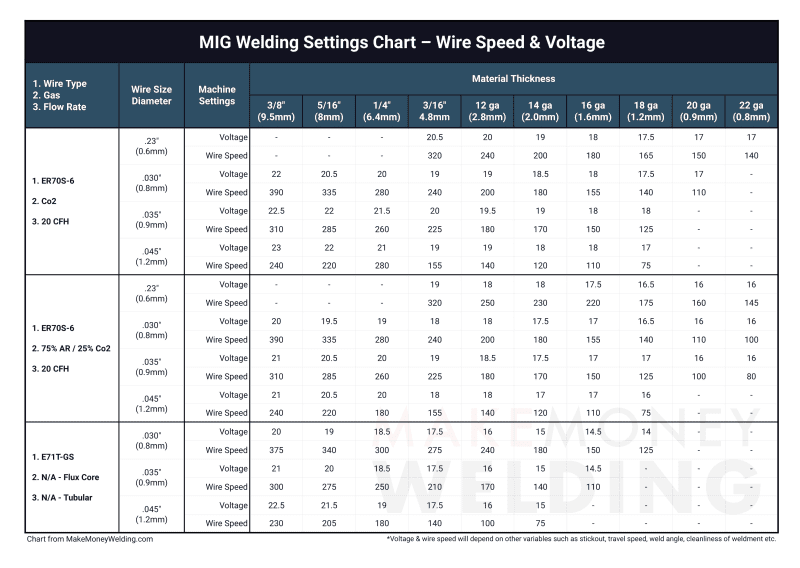

Miller Voltage And Wire Speed Chart . 10 rows this calculator is intended as a guide to initial power and wire feed settings for people new to welding. wire size & wire feed speed: the general rule, also known as the thumb rule, states you should use 1 amp for.001 inch of material thickness. But before using these values, we suggest that you have a decent. setting the wire speed for mig welding involves understanding the correlation between wire speed, voltage, and amperage. A higher wire speed requires. download the app version of the weld setting calculator for easy reference! So, for example, if you are welding 1/8″ mild. Co 2 gas is economical and has deeper penetration on steel, but may be too. Shielding gas & voltage range: i’ve included a chart below to help you select your voltage by inspecting the bead. Wire feed speed (wfs) affects your heat level. here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders.

from makemoneywelding.com

A higher wire speed requires. wire size & wire feed speed: So, for example, if you are welding 1/8″ mild. here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. setting the wire speed for mig welding involves understanding the correlation between wire speed, voltage, and amperage. 10 rows this calculator is intended as a guide to initial power and wire feed settings for people new to welding. Shielding gas & voltage range: But before using these values, we suggest that you have a decent. download the app version of the weld setting calculator for easy reference! Wire feed speed (wfs) affects your heat level.

Important MIG Welder Settings You Need to Know (with Chart)

Miller Voltage And Wire Speed Chart Co 2 gas is economical and has deeper penetration on steel, but may be too. But before using these values, we suggest that you have a decent. A higher wire speed requires. the general rule, also known as the thumb rule, states you should use 1 amp for.001 inch of material thickness. wire size & wire feed speed: setting the wire speed for mig welding involves understanding the correlation between wire speed, voltage, and amperage. Shielding gas & voltage range: here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. i’ve included a chart below to help you select your voltage by inspecting the bead. 10 rows this calculator is intended as a guide to initial power and wire feed settings for people new to welding. Wire feed speed (wfs) affects your heat level. So, for example, if you are welding 1/8″ mild. download the app version of the weld setting calculator for easy reference! Co 2 gas is economical and has deeper penetration on steel, but may be too.

From www.hotrod.com

The New Miller Multimatic 215 Easy to Use & Carry Hot Rod Network Miller Voltage And Wire Speed Chart download the app version of the weld setting calculator for easy reference! Co 2 gas is economical and has deeper penetration on steel, but may be too. But before using these values, we suggest that you have a decent. So, for example, if you are welding 1/8″ mild. i’ve included a chart below to help you select your. Miller Voltage And Wire Speed Chart.

From schematicspinnerethf.z22.web.core.windows.net

Millermatic 250 Settings Chart Pdf Miller Voltage And Wire Speed Chart wire size & wire feed speed: i’ve included a chart below to help you select your voltage by inspecting the bead. A higher wire speed requires. download the app version of the weld setting calculator for easy reference! the general rule, also known as the thumb rule, states you should use 1 amp for.001 inch of. Miller Voltage And Wire Speed Chart.

From www.instructables.com

Basics of MIG Welding 17 Steps (with Pictures) Instructables Miller Voltage And Wire Speed Chart i’ve included a chart below to help you select your voltage by inspecting the bead. So, for example, if you are welding 1/8″ mild. setting the wire speed for mig welding involves understanding the correlation between wire speed, voltage, and amperage. Wire feed speed (wfs) affects your heat level. But before using these values, we suggest that you. Miller Voltage And Wire Speed Chart.

From wiredataobscurebtta.z4.web.core.windows.net

Mil Spec Wire Color Code Chart Miller Voltage And Wire Speed Chart 10 rows this calculator is intended as a guide to initial power and wire feed settings for people new to welding. download the app version of the weld setting calculator for easy reference! wire size & wire feed speed: A higher wire speed requires. Shielding gas & voltage range: i’ve included a chart below to help. Miller Voltage And Wire Speed Chart.

From www.hotrod.com

LifeChanging Tools MIG Welder Hot Rod Network Miller Voltage And Wire Speed Chart here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. A higher wire speed requires. setting the wire speed for mig welding involves understanding the correlation between wire speed, voltage, and amperage. Shielding gas & voltage range: download the app version of the weld setting calculator for easy reference! . Miller Voltage And Wire Speed Chart.

From louisrichardson.z13.web.core.windows.net

Mig Welding Amps To Metal Thickness Chart Miller Voltage And Wire Speed Chart i’ve included a chart below to help you select your voltage by inspecting the bead. here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. Wire feed speed (wfs) affects your heat level. A higher wire speed requires. Co 2 gas is economical and has deeper penetration on steel, but may. Miller Voltage And Wire Speed Chart.

From dgtcom.com.br

MIG Welding Settings Explained Wire Speed Voltage Chart, 55 OFF Miller Voltage And Wire Speed Chart wire size & wire feed speed: 10 rows this calculator is intended as a guide to initial power and wire feed settings for people new to welding. So, for example, if you are welding 1/8″ mild. Co 2 gas is economical and has deeper penetration on steel, but may be too. A higher wire speed requires. Wire feed. Miller Voltage And Wire Speed Chart.

From schematiclibfriars99.z22.web.core.windows.net

Miller 130 Welder Wire Guide Miller Voltage And Wire Speed Chart setting the wire speed for mig welding involves understanding the correlation between wire speed, voltage, and amperage. here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. Shielding gas & voltage range: download the app version of the weld setting calculator for easy reference! wire size & wire feed. Miller Voltage And Wire Speed Chart.

From sophiemetcalfe.z13.web.core.windows.net

Millermatic 252 Settings Chart Miller Voltage And Wire Speed Chart So, for example, if you are welding 1/8″ mild. But before using these values, we suggest that you have a decent. Shielding gas & voltage range: Co 2 gas is economical and has deeper penetration on steel, but may be too. i’ve included a chart below to help you select your voltage by inspecting the bead. 10 rows. Miller Voltage And Wire Speed Chart.

From www.pinterest.com

Pin on lokhandwala Shabbir. Miller Voltage And Wire Speed Chart But before using these values, we suggest that you have a decent. the general rule, also known as the thumb rule, states you should use 1 amp for.001 inch of material thickness. Co 2 gas is economical and has deeper penetration on steel, but may be too. download the app version of the weld setting calculator for easy. Miller Voltage And Wire Speed Chart.

From gowelding.org

MIG Welding Aluminum Electrodes, Gasses, Welder Setting & Equipment Miller Voltage And Wire Speed Chart here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. i’ve included a chart below to help you select your voltage by inspecting the bead. download the app version of the weld setting calculator for easy reference! wire size & wire feed speed: setting the wire speed for. Miller Voltage And Wire Speed Chart.

From www.hotrod.com

Using the Millermatic 211 MIG Welder Hot Rod Network Miller Voltage And Wire Speed Chart A higher wire speed requires. Shielding gas & voltage range: download the app version of the weld setting calculator for easy reference! setting the wire speed for mig welding involves understanding the correlation between wire speed, voltage, and amperage. the general rule, also known as the thumb rule, states you should use 1 amp for.001 inch of. Miller Voltage And Wire Speed Chart.

From masonlong.z19.web.core.windows.net

Mig Welding Voltage Chart Miller Voltage And Wire Speed Chart So, for example, if you are welding 1/8″ mild. Shielding gas & voltage range: i’ve included a chart below to help you select your voltage by inspecting the bead. But before using these values, we suggest that you have a decent. wire size & wire feed speed: A higher wire speed requires. download the app version of. Miller Voltage And Wire Speed Chart.

From www.thewelderswarehouse.com

3 Easy to follow Steps for Perfect Mig Wire Feed Speed Miller Voltage And Wire Speed Chart So, for example, if you are welding 1/8″ mild. here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. Wire feed speed (wfs) affects your heat level. 10 rows this calculator is intended as a guide to initial power and wire feed settings for people new to welding. Co 2 gas. Miller Voltage And Wire Speed Chart.

From diagramfixeggers.z21.web.core.windows.net

Arc Welding Voltage And Current Chart Pdf Miller Voltage And Wire Speed Chart So, for example, if you are welding 1/8″ mild. Co 2 gas is economical and has deeper penetration on steel, but may be too. Shielding gas & voltage range: wire size & wire feed speed: i’ve included a chart below to help you select your voltage by inspecting the bead. Wire feed speed (wfs) affects your heat level.. Miller Voltage And Wire Speed Chart.

From www.mig-welding.co.uk

Tell us your fave volts/wirespeed settings. MIG Welding Forum Miller Voltage And Wire Speed Chart Shielding gas & voltage range: i’ve included a chart below to help you select your voltage by inspecting the bead. But before using these values, we suggest that you have a decent. Co 2 gas is economical and has deeper penetration on steel, but may be too. here is a chart showing the wire speed and voltage speed. Miller Voltage And Wire Speed Chart.

From schematicspinnerethf.z22.web.core.windows.net

Mig Welding Wire Chart Miller Voltage And Wire Speed Chart setting the wire speed for mig welding involves understanding the correlation between wire speed, voltage, and amperage. here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. So, for example, if you are welding 1/8″ mild. Shielding gas & voltage range: But before using these values, we suggest that you have. Miller Voltage And Wire Speed Chart.

From maker-hub.georgefox.edu

MIG Welder makerhub Miller Voltage And Wire Speed Chart 10 rows this calculator is intended as a guide to initial power and wire feed settings for people new to welding. i’ve included a chart below to help you select your voltage by inspecting the bead. here is a chart showing the wire speed and voltage speed settings that suit lincoln mig welders. download the app. Miller Voltage And Wire Speed Chart.